Services Solutions

Explore a world of creative solutions and innovation tailored to your needs.

Customer-centric

“Customer-centric” is our commitment. We believe that perfect service is as important as sales. Our company’s consistent service tenet is to satisfy customers with excellent product quality and good reputation.

Customized material development 1

Precisely match your needs

We provide full-process material development services from formula design to performance optimization, covering:

-Material modification: adjust hardness, temperature resistance, flame retardant grade (UL94 V0~HB)

-Color customization: provide Pantone color card matching, support transparent/solid color/fluorescent effects

-Functional enhancement: anti-UV, anti-hydrolysis, conductive/antistatic and other special needs

Applicable fields:

✓ Automotive seals ✓ Optical fiber sheaths ✓ Aluminum alloy window insulation strips ✓ Electronic and electrical housings

Technical support and testing 2

Full escort from laboratory to mass production

Free samples: Provide 200g~5kg small batch trial production materials

Performance testing:

▶ Mechanical performance test (tensile/bending/impact)

▶ Aging test (QUV accelerated aging 3000 hours)

▶ Flame retardant/environmental certification (UL/TUV/SGS report)

Production guidance: Provide injection molding/extrusion process parameter package

Rapid response supply chain 3

Stable delivery · Global reach

Capacity guarantee: 30+ production lines, monthly capacity exceeds 2,000 tons

Flexible inventory: PA66/TPEE/PE standard grades are always available

Logistics network: Support land/sea transportation, provide trade terms such as EXW/FOB

Industry solutions (case presentation) 4

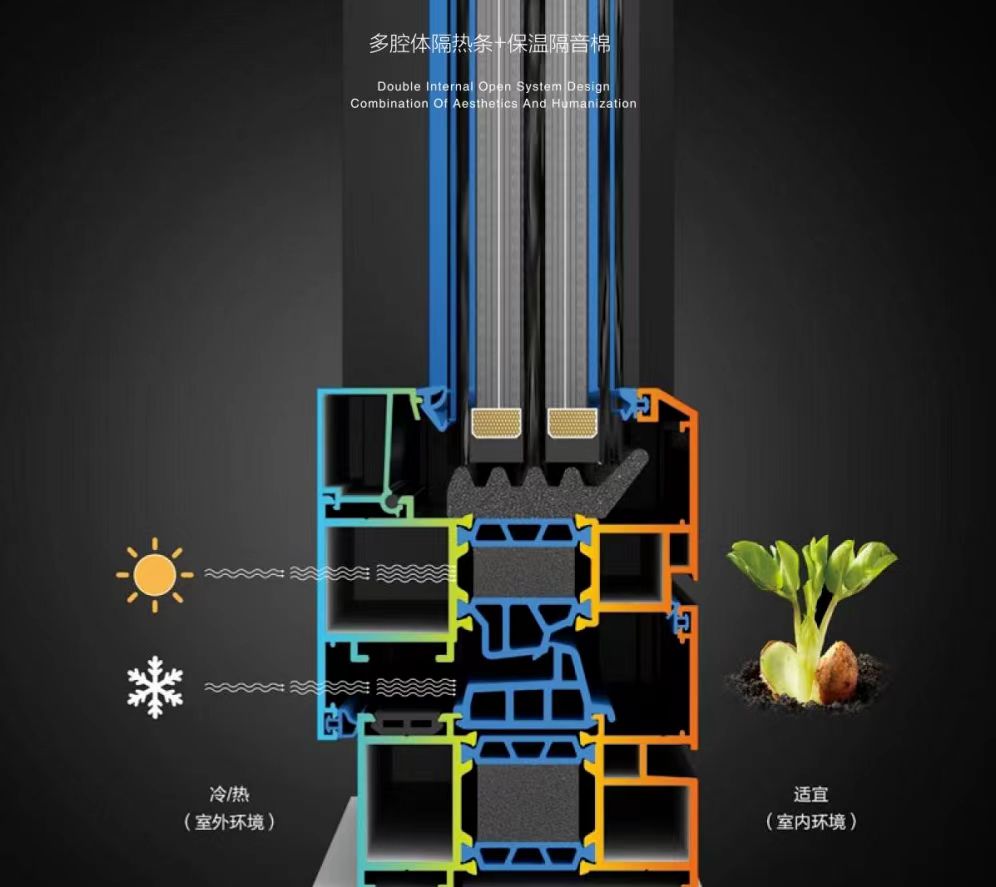

① Aluminum alloy doors and windows

Problem: Ordinary aluminum alloy windows transfer a lot of heat, resulting in huge energy loss.

Solution: Add PA66 insulation strip material to cut off the transfer of indoor and outdoor heat through profiles

Result: Block the heat conduction between metal profiles, significantly improve the heat insulation, sound insulation and energy saving performance of windows.

② 5G optical cable field

Problem: Submarine cable sheath requires salt spray resistance + 50-year life

Solution: HDPE + nano-silicon dioxide composite modification

Result: The product has passed the Taier certification

Why Choose Us

Custom Engineering Plastics

–Optical cable sheath material supplier

–Aluminum alloy doors and windows, nylon insulation strip supplier for curtain wall

–Thermoplastic polyester elastomer supplier

quality assurance

15,000㎡ intelligent factory

Expertise

12 years of focus on engineering plastics (established in 2011)

Collaboration

1V1 technical manager to follow up throughout the process

Stay Connected with Us

Let\’s Create Together

📞 Tel: +86 18627800113

📧 Email: will@zaicci.com

🌐 Official website: www.zaicci.com