Doors and windows are the bridges between people and nature indoors. As a barrier to protect home life, the quality of doors and windows seriously affects people’s daily lives. As an important component of today’s thermally insulated aluminum doors and windows, what role do insulation strips play in the entire door and window?

What are insulation strips?

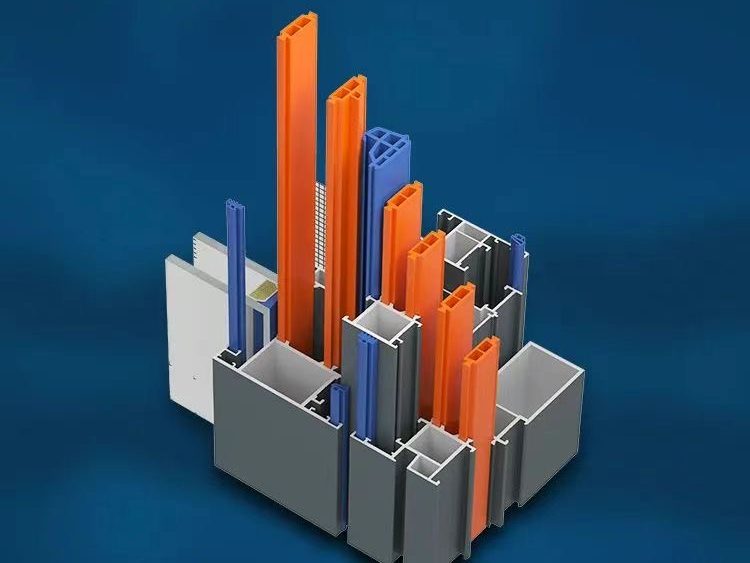

(1) The thermal conductivity of aluminum alloy doors and windows is too high, which makes it easy for indoor and outdoor temperatures to transfer to each other, increasing indoor energy consumption. On this basis, the original integrated profile is divided into two parts, and the two parts are connected together by mechanical means of insulation material to improve the performance of doors and windows. This is the insulation strip.

The importance of insulation strips

(2) The insulation strips of doors and windows are closely related to the five major performances of the entire door and window. The insulation strips of doors and windows are the core components of the insulation profiles. They not only affect the heat transfer effect of doors and windows, but are also the connecting parts of the aluminum profiles on both sides. They play an important role in the stability and safety of the insulation box of doors and windows. High-quality insulation strips and standard installation methods can greatly improve the overall performance of doors and windows, providing residents with a more comfortable experience.

Material of insulation strips

(3) The nature of the use of insulation strips determines that they must have both high strength and low conductivity. Otherwise, insufficient strength will cause the aluminum profile to break at the connection of the insulation strip or lose its insulation value. Therefore, the material of the insulation strip is very important. At present, there are two main materials for insulation strips on the market: PA66 insulation strips and PVC insulation strips.

First, let us first understand the difference between PA66 insulation strips and PVC insulation strips:

The main components of PA66 insulation strips are not less than 65% polyamide 66 and 25%±2.5% glass fiber, that is, PA66-GF25. The tensile strength of PA66 insulation strips can easily reach more than 80MPa, while PVC insulation strips can only reach 35~48MPa.

In addition to tensile strength, the heat deformation temperature of the two is also very different, PA66 insulation strip 240°, PVC insulation strip 80°. Therefore, even in the high temperature exposure in summer, PA66 can still ensure the dimensional accuracy of 0.5mm in the clamp of the aluminum profile bite, and the clamp will not be too large or too small, and because the clamps are completely different from the aluminum profile, there will be biased stress, resulting in loose grooves and leakage.

However, PVC insulation strips are sensitive to light and heat, and will deform as long as the temperature is slightly higher.

In addition to the above differences, we also need to pay attention to its expansion coefficient. We know that the linear expansion coefficient of aluminum profiles is 2.35×10-5, PA66 material is 3.0×10-5, and PVC material is 8.0×10-5. It can be seen that the linear expansion coefficient of PA66 material and aluminum profiles is similar, which can ensure synchronous expansion and contraction and maintain the integrity of the insulation strip and aluminum profile.

At present, society is increasingly advocating low-carbon life, and the same is true for the selection of door and window materials. PA66 insulation strips are durable and not easy to age, while PVC insulation strips are very easy to age due to their photosensitivity. PA66 is polyamide, which is safe and environmentally friendly, while PVC is polyvinyl chloride, one of the three types of carcinogens, and its combustion will produce toxic gases, which are harmful to human health. Doors and windows are a whole, and each part is crucial. Choosing good insulation strips can also ensure the safety and service life of doors and windows.